Dye, ink and pigment .

Braziel wood was an important source for red- and pink-coloured hues in the Middle Ages. In a lye solution, the red-coloured wood gives a deep red colour, which can then be used again as a dye for colouring fabrics. It can also be used to make ink or a pigment.

In this post, I want to tell something about it but mainly show how to make a pigment from it. I will now leave out the making of ink and the dyeing of fabrics, for which brazil wood was also widely used.

Braziel wood was mainly from Ceylon in the Middle Ages. The word braziel has the same word root as the English word ‘brazian’ meaning coppersmith. So the origin of the word had more to do with the glowing red colour of the wood, and the shine of the copper, than it was geographically determined. This is also true what as mentioned, Ceylon was a major centre for the supply of the red wood in the Middle Ages. It was then transported via Alexandria and Baghdad to Europe in large quantities. And that was even before the discovery of Brazil!

The wood first came from the de Braziel tree imported in pieces from Ceylon (Caesalpinia Brasiliensis) and later, after the discovery of America, the (Caesalpina Echinata) from the Caribbean or South America. All contain the red dye: Brasiline.

When the Portuguese colonised what is now Brazil at the beginning of the 16th century, they encountered redwood trees that they called Brasiline trees. Europeans often named their colony after the trade goods from that area. So the new country was named Brazil.

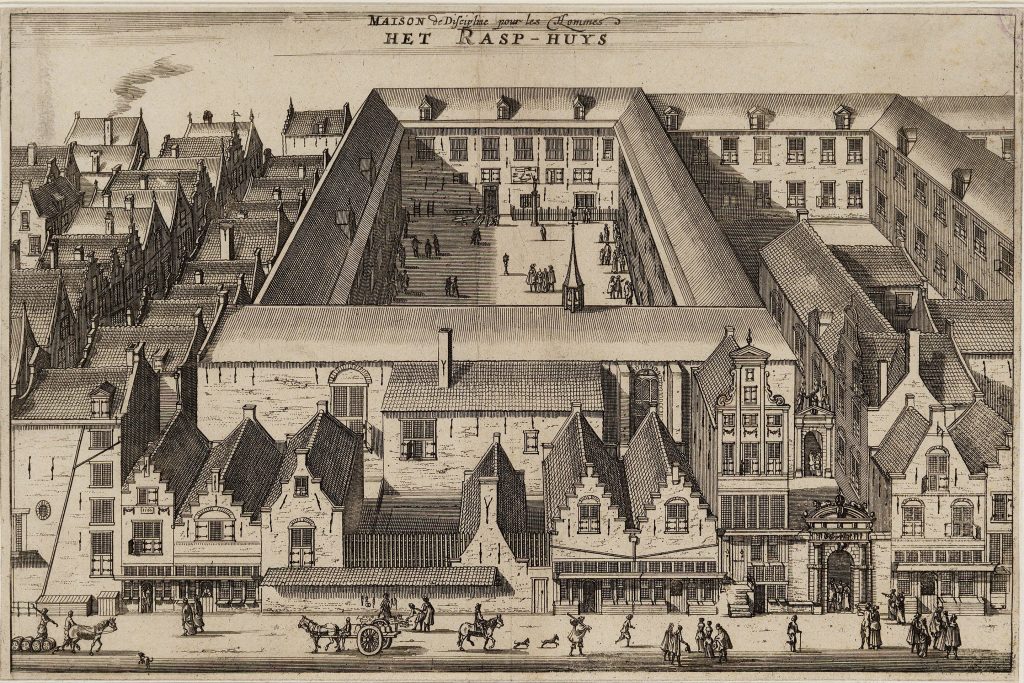

The wood was not only used for making ink or pigments but was also widely used as a dye for textiles. It was highly sought after by European textile dyers. The wood was sold in blocks and had to be crushed. Pieces were scraped off with glass because the finer, the better the extraction of the dye. This was a tough and difficult job and was sometimes left to prisoners. From the 16th century to 1815, there was a so-called: ‘Rasphuis’ a former Claris convent in Amsterdam. Only male prisoners were placed there and they, were allowed to do the hard work.

Currently, the Braziel tree is protected, the wood may no longer be imported. As a replacement, the so-called : ‘Sappan wood’ is then used.

The Rasp-Huys. Source: Stadsarchief Amsterdam

Below is the photographic progression of an authentic recipe from 1400. Many, many recipes can be found for obtaining dye, ink, and pigment from Brazils. My recipe comes from the anonymous work: De Arte Illuminandi. I provide a description of the complete recipe at the bottom of the post.

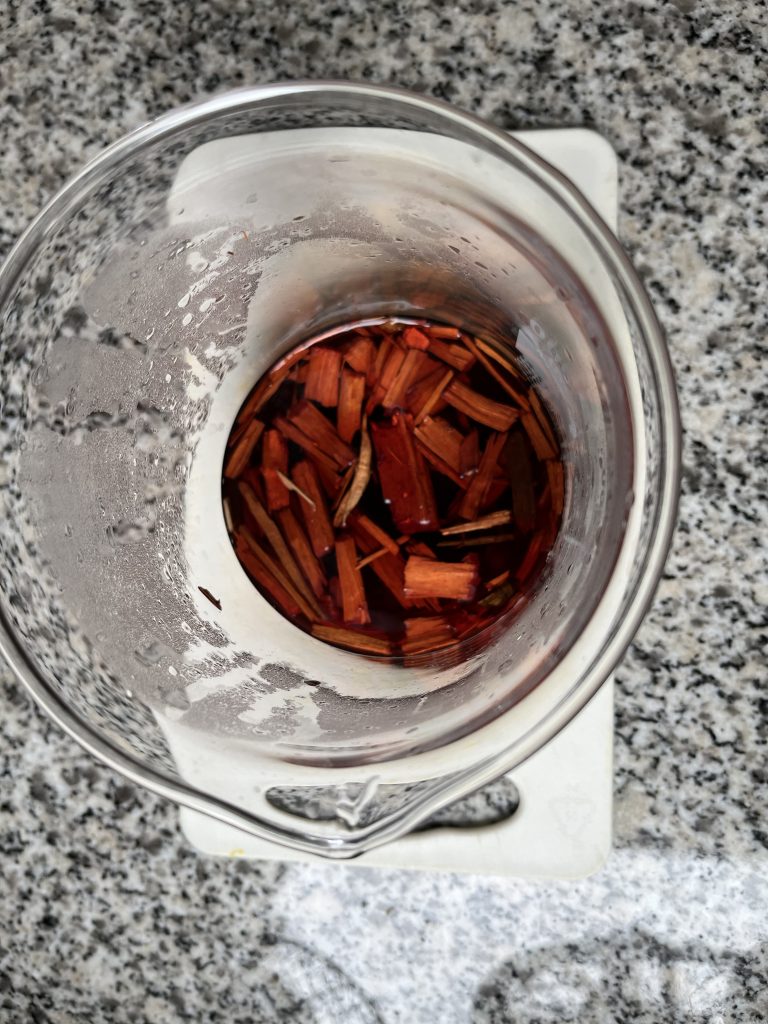

It is important to shave the wood as finely as possible. That way you extract more Brasilia, (the red dye) from the wood. If you wet the wood with water, it becomes somewhat reddish. But the best way is to dissolve the dye from the wood in an alum or lye solution. For my lye solution, I used ash from the fireplace. Pouring it into a filter with hot water produces a slightly coloured decoction of lye. The best is ash from burnt oak or that from vines. I myself regularly make some bags of wood ash that I first strain with a strainer.

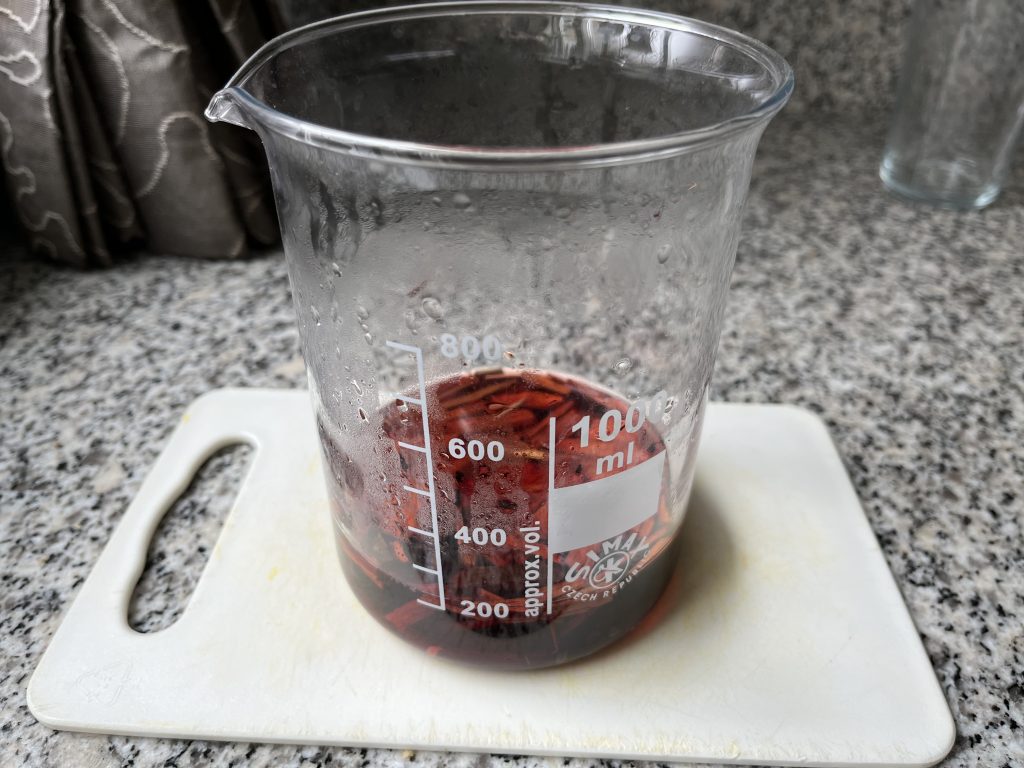

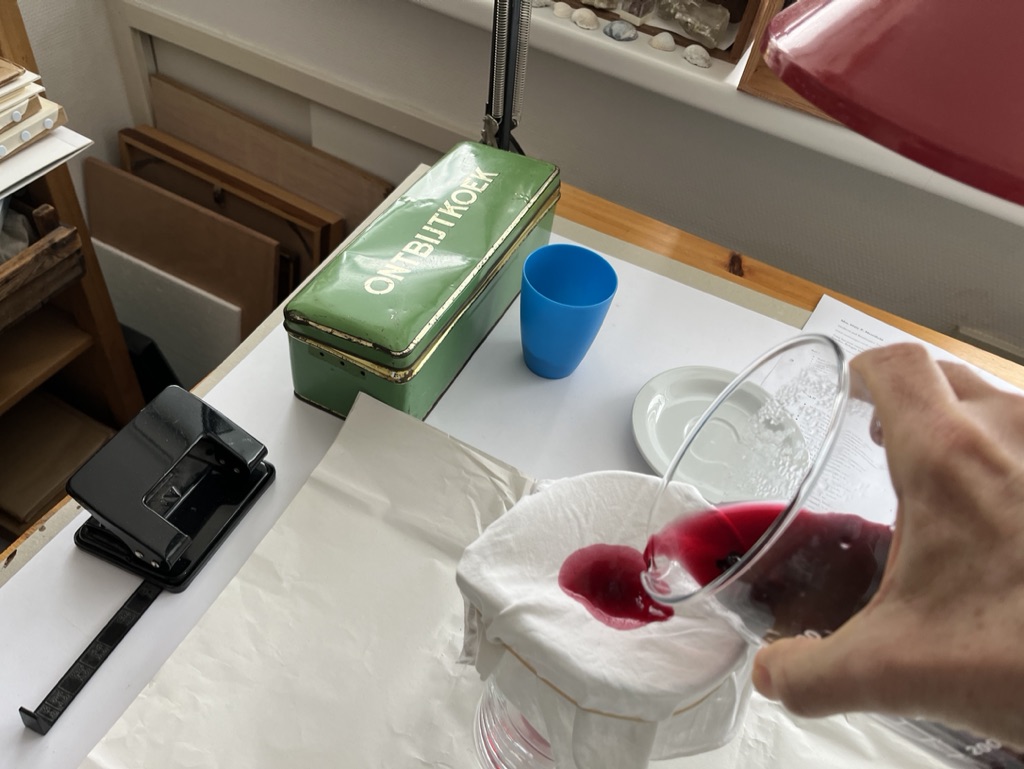

We let the lye soak into the wood chips for a day and overnight. Then we filter the solution through a linen cloth. No small wood particles should remain in the solution.

We now have the purified, coloured lye solution in a dish that is heat-resistant. We take as much marble abrasive as alum, equal to the weight of the brazil in the lye solution.

Twenty grams: Brazilwood

Twenty grams of Marble Grind

Twenty grams of alum

We now add the marble grind and do so while stirring. We heat the solution but be careful not to let it boil.

Then we also add the crystallised alum while stirring.

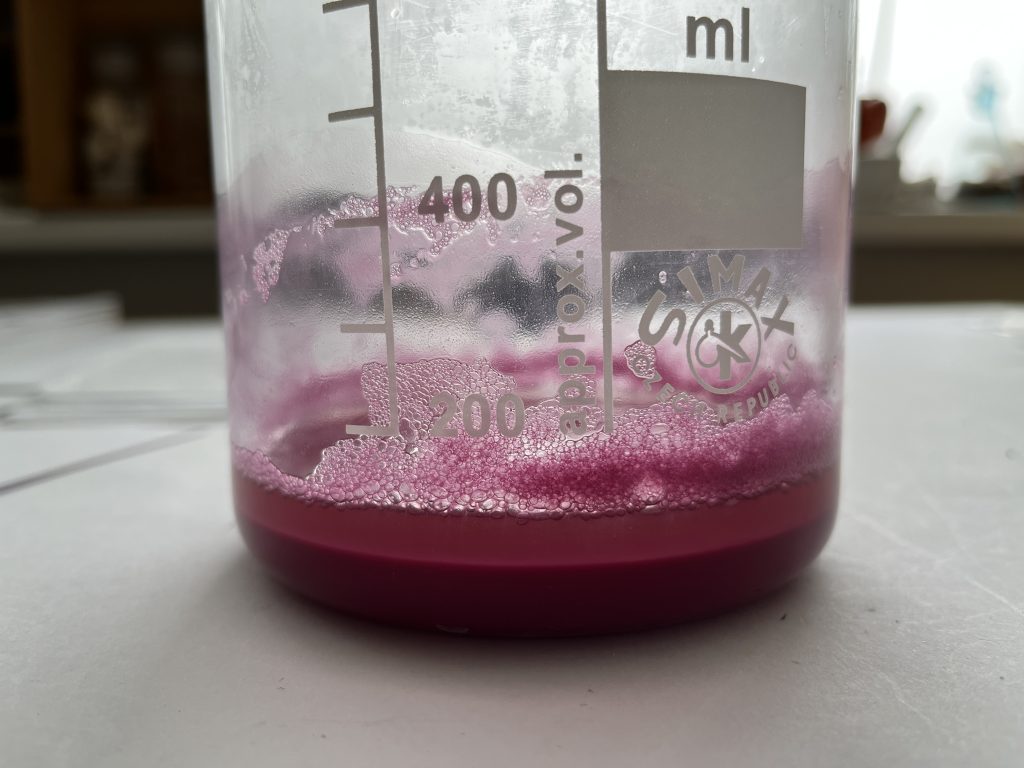

The heated mass may bubble considerably. It is therefore advisable to take a tall beaker.

We take the fizzy mass off the electric hob and let it cool. The foam will subside and the next day we can pour off the water.

After pouring off the water, we can take out the sediment with a spoon.

I then applied the remaining mass to the bottom of the cup on a plate of satin glass to let it dry further. Do put a lid of a box above it for any dust falling down.

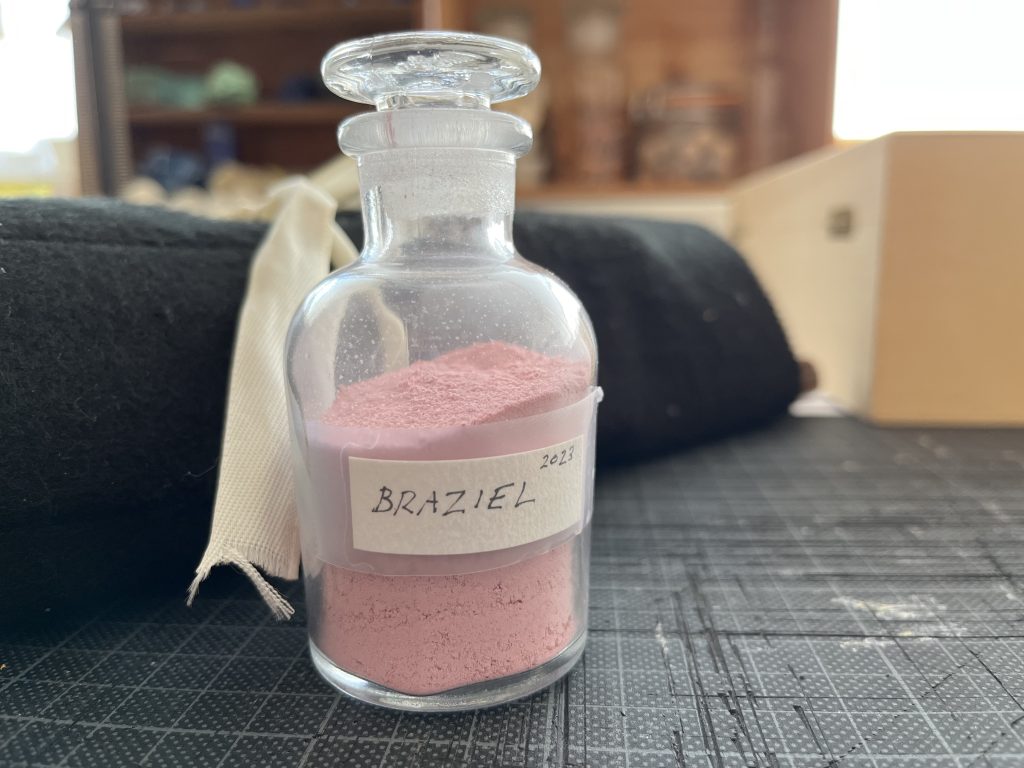

After the mass had dried completely, you can grind it further with a glass muller. Et voilà there is the pigment with which you can make pretty shades of pink.

Rosaceum is a pink pigment made by adding white lime to a solution of Brazile wood. The process is shown in the pictures above.

Above we see an image of the drying pigment. Here I have added cochineal in addition to brazil wood. This makes the colour deeper and more intense. The ratio here is 50% brazilwood and 50% cochineal, dissolved in lye and also with marble grind and alum.

Below is the recipe from the Arte Illuminandi

‘The rose colour meaning pink, which is commonly used on parchment to colour clothes or leaves or parts of letters and also how to make it in transparent form, to shade leaves or parts of letters.

The opaque colour pink is made as follows. Take some of the best brazilwood( and this is the way to test it; when you put it in your mouth it tastes sweet and when you chew it it turns pink).

Using a knife or a piece of glass, scrape off as much as you need. ( For my experiment: 20 grams of brazil wood in pieces). Put it in the lye you made ash from burnt wood from the vine or oak. ( For my experiment: I took a filter bag no 2 full of wood ash from the fireplace. It was not oak. Poured it with boiling water until I had 200 ml of lye).

Put it in a heat-resistant pot or bowl and let the lye cover the brazil wood so that anything soluble will be dissolved by the lye. Leave it in this lye for a day and a night to soften. Then put it on the fire and bring it to a boil, but do not let it boil and stir it often with a stick. Then check how much brazil wood there was and take from the same amount by weight of beautiful white marble ground very thoroughly to a very fine powder and as much pure alum as brazil wood. (For my experiment: 20 grams of marble grind/powder and 20 grams of crystallised alum).

Mix them gradually in the bowl until the resulting foam disappears again, and it is well coloured

And know that some say that the lye after it is well coloured should be sieved and put into a glazed dish and after heating, they add the alum and marble. And that will take on the colour immediately and the water will be almost clear on top and you pour it off carefully. And that is better.(In my experiment, I followed this method).

The lye should be two weeks old, either made with rainwater that has stood to decay in a stone vessel. Or as is usual in a hollow wooden vessel, because that water is the best and the best colour is made with it.

If you want to keep it for a long time, mix it with gum water and let it dry, and then store it in small pieces.

In summary:

200 ml lye

20 grams of brazil wood

20 grams of marble grind

20 grams of crystallised alum

Sieve cloth, linen

Pots , heat-resistant dish

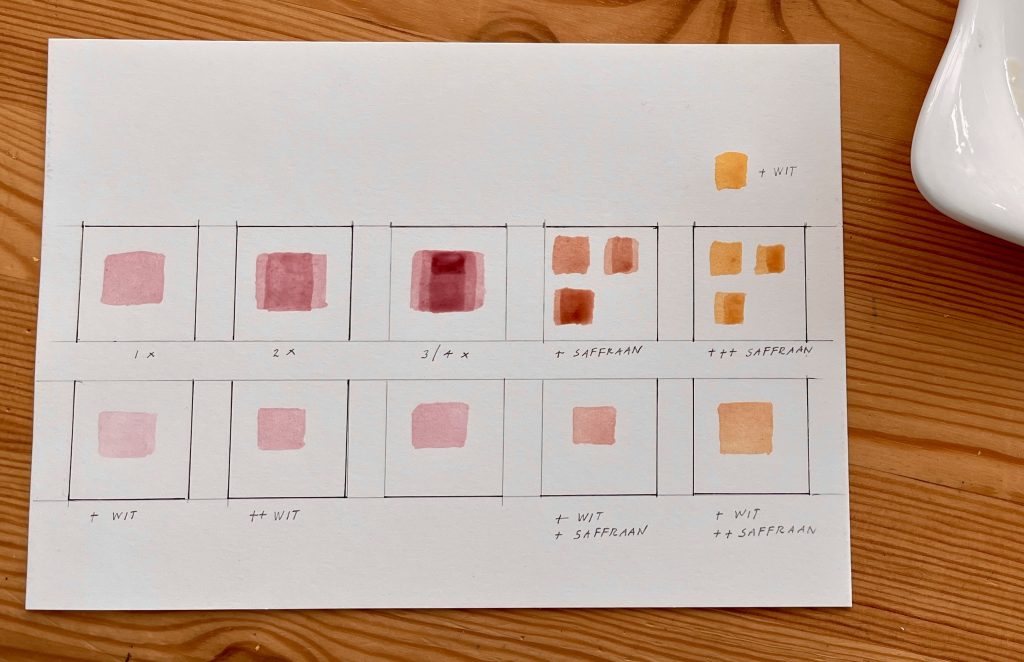

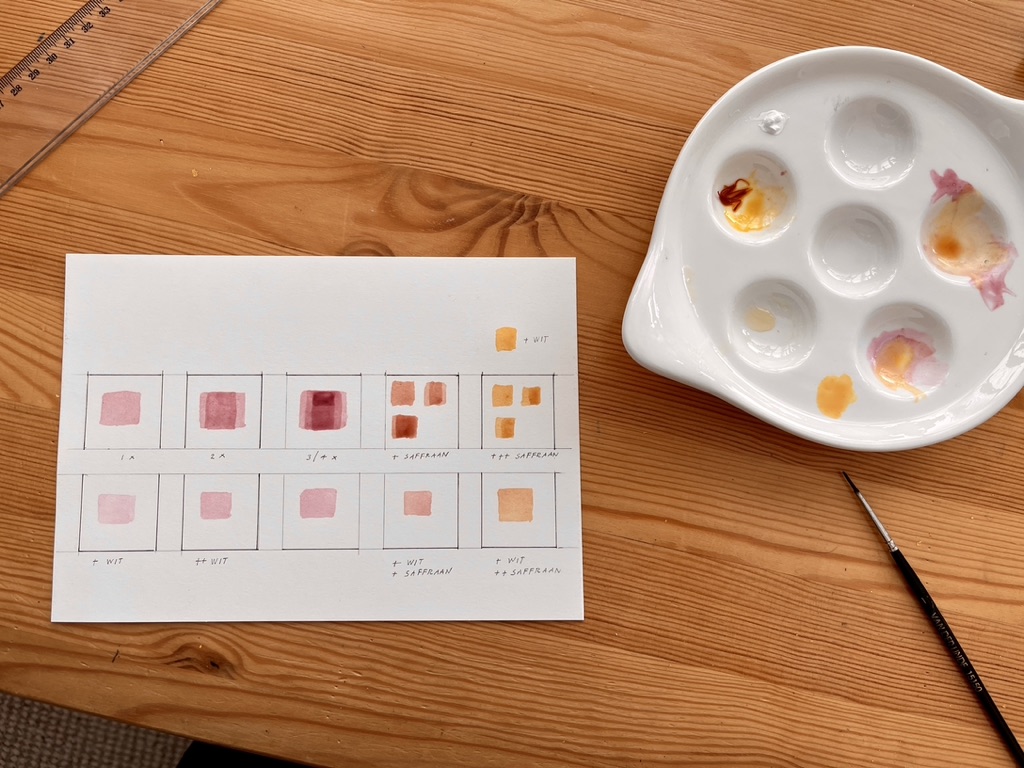

In the different tests, I used the made pink pigment painted in several layers on top of each other , saffron and white.